Ethylene, a plant hormone produced by fresh fruits and vegetables, are often found in high levels in cold chain facilities.

PURESPACE’s proprietary filter technology effectively removes ethylene from the air, preventing ethylene’s accelerated ripening effects that reduce produce quality.

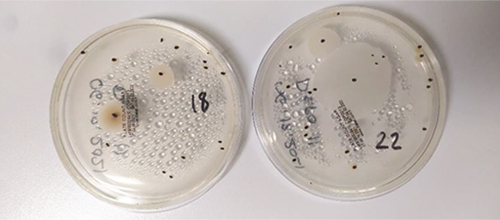

[ Fresh Produce Kept at 10 ppb vs. 1,000 ppb Ethylene ]

Ethylene is well known to cause color change, softening, and rotting of fresh fruits and vegetables. It exists only in trace amounts in open air, however produce warehouses and trucks often have over 100 or 1,000 ppb. Reducing this high level can significantly reduce your loss and improve fresh qualities, so your customers can enjoy your produce fresher and longer.

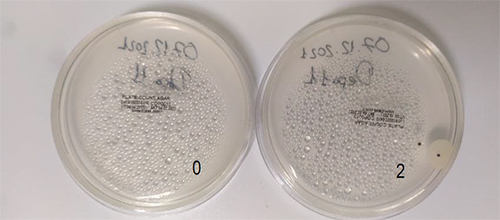

[ Airborne Microbe Comparison ]

PURESPACE also effectively removes airborne microbes to delay rotting of fresh produce.